I-conductivity ekhethekile Ulayini wokudlulisa isignali ephezulu Ingxubevange yocingo oluyindilinga enamelled Izakhiwo ezinomshini ophezulu zingenziwa ngokwezifiso

Iyini i-alloy wire

1.1 Ukuze kuthuthukiswe ukusebenza okukhethekile kocingo lwe-enamelled, i-alloy wire iyi-enamelled wire umqhubi wayo wenziwe nge-alloy yethusi. I-alloy wire ine-conductivity kagesi ekhethekile, izakhiwo zemishini, ukumelana nokukhathala kanye nokumelana nokugoba okuhle kakhulu. Ukuze uhlangabezane nezidingo ezikhethekile zokusetshenziswa kwamakhasimende, inkampani yethu inikeza izintambo ezihlukahlukene ze-alloy enamelled. Ukuze siqinise izici ezithile zocingo, sizoqhubekisela phambili ukucubungula izintambo ze-alloy ukuhlangabezana nezidingo zokusetshenziswa kwamakhasimende.

1.2. Singahlinzeka nge-copper silver alloy, i-copper tin alloy, i-copper nickel alloy, i-silver plating, i-nickel plating nezinye izintambo ze-alloy enamelled, kanye nama-conductor alloy ngokusho kwezicelo ezahlukene.

Uhlobo lwe-alloy wire enamelled

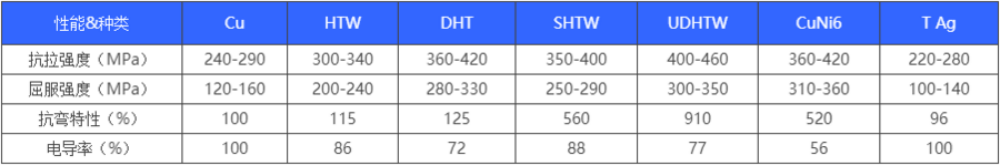

2.1 Izici zezintambo ezidonsa kanzima (HTW, DHT, SHTW, UDHTW):

I-high tension wire iyi-alloy yethusi self-adhesive wire enamelled eklanyelwe ngokukhethekile izidingo zokusetshenziswa kwezakhiwo eziphezulu zemishini. Amamodeli ayo aqanjwe ngokuthi HTW, DHT, SHTW, UDHTW; Isetshenziswa ezinhlelweni ezinezidingo eziphezulu zokumelana nokugoba nokuthembeka. Intambo ye-tension ephezulu inokumelana ne-tension ephakeme, ukwethembeka, i-conductivity kanye nokumelana nokugoba kunocingo lwethusi olungenasici.

isici:

·Amandla e-tensile aphakeme ngo-20-90% kunalawo ocingo lwethusi olunwetshiwe, olufanele ukusonteka ngesivinini esikhulu, futhi umlenze we-solder akulula ukuphuka.

·Ukuqhuba>77%.

·Isisekelo se-insulating layer, i-self-adhesive layer kanye ne-enamelled copper wire ziyefana.

·Ukusebenza kokushisela okuqondile kuyafana nokwezintambo zethusi ezinoqweqwe oluqinile.

2.2 Izici eziphezulu ze-impedance alloy wire (CuNi6):

I-high impedance alloy wire iyi-copper alloy enamelled wire eyenzelwe ngokukhethekile izidingo zesicelo se-impedance, futhi imodeli yayo ibizwa ngokuthi i-CuNi6;

isici:

·Inani le-impedance imitha liphindwe izikhathi ezingu-6-8 kunalelo locingo olunoqweqwe lwekhopha, olufanele ijeneretha noma ikhoyili ekhethekile esetshenziselwa ukulungisa inani le-Q.

·Isisekelo se-insulating layer, i-self-adhesive layer kanye ne-enamelled copper wire ziyefana.

·Ukusebenza kokushisela okuqondile kuyafana nokwezintambo zethusi ezinoqweqwe oluqinile.

·Izici ezinhle kakhulu zokudlulisa isignali.

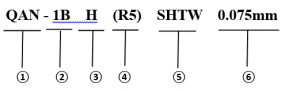

2.3 Incazelo yekhodi yomkhiqizo:

1. Thayipha ikhodi yesendlalelo se-insulating

AN=I-UEW eshiselayo

ZN=I-PEW engashiseki

XYN=I-EIW engashiseki

2. Ukujiya kwefilimu kapende (1,2,3, bhekisa ku-IEC namazinga ekhasimende).

3. Ibanga lokumelana nokushisa kwe-insulation

F=155

H=Ikilasi 180

I-S * imele ithini le-soldering lokushisa eliphansi

4. Uhlobo longqimba oluzinamathelayo (ungqimba oluzinamathelisa olungu-R oluthambile lokushisa lwesibili ≤ 130 ℃, ungqimba oluzinamathelisa olungu-R5 oluthambisayo lwesibili lokushisa ≤ 160 ℃, ungqimba oluzinamathelayo lwe-R7 izinga lokushisa lesibili lokuthambisa ≤ 190 ℃, ungqimba olunamathelayo lwe-C ukusetshenziswa okubili kotshwala komoya oshisayo, ungqimba olunamathelayo lwe-SV luqinisa ukushisa).

5. Isigaba se-alloy

HTW=Intambo evamile edonsa kanzima

DHT=Intambo yocingo oluqinile

SHTW=intambo enamandla kakhulu

UDHTW=ucingo olunamandla kakhulu

6. Ububanzi be-conductor (mm).

Ibanga lomkhiqizo: Φ 0.030-0.15mm (AWG52-34)

.jpg)

-300x300.jpg)

2-300x300.jpg)

1-300x300.jpg)

1-300x300.jpg)